When we hear the word “plastic”, most of us imagine piles of non-degradable waste, bottles floating in the ocean, or environmental damage. But the truth is: not all plastics are the same. With the right material choice and proper waste management, some plastics can actually be part of the solution rather than the problem.

One of the most promising materials is PP (Polypropylene) – a versatile plastic found in our everyday lives, from food packaging and household goods to medical supplies. What makes PP stand out is its unique balance between functionality, cost-effectiveness, and sustainability.

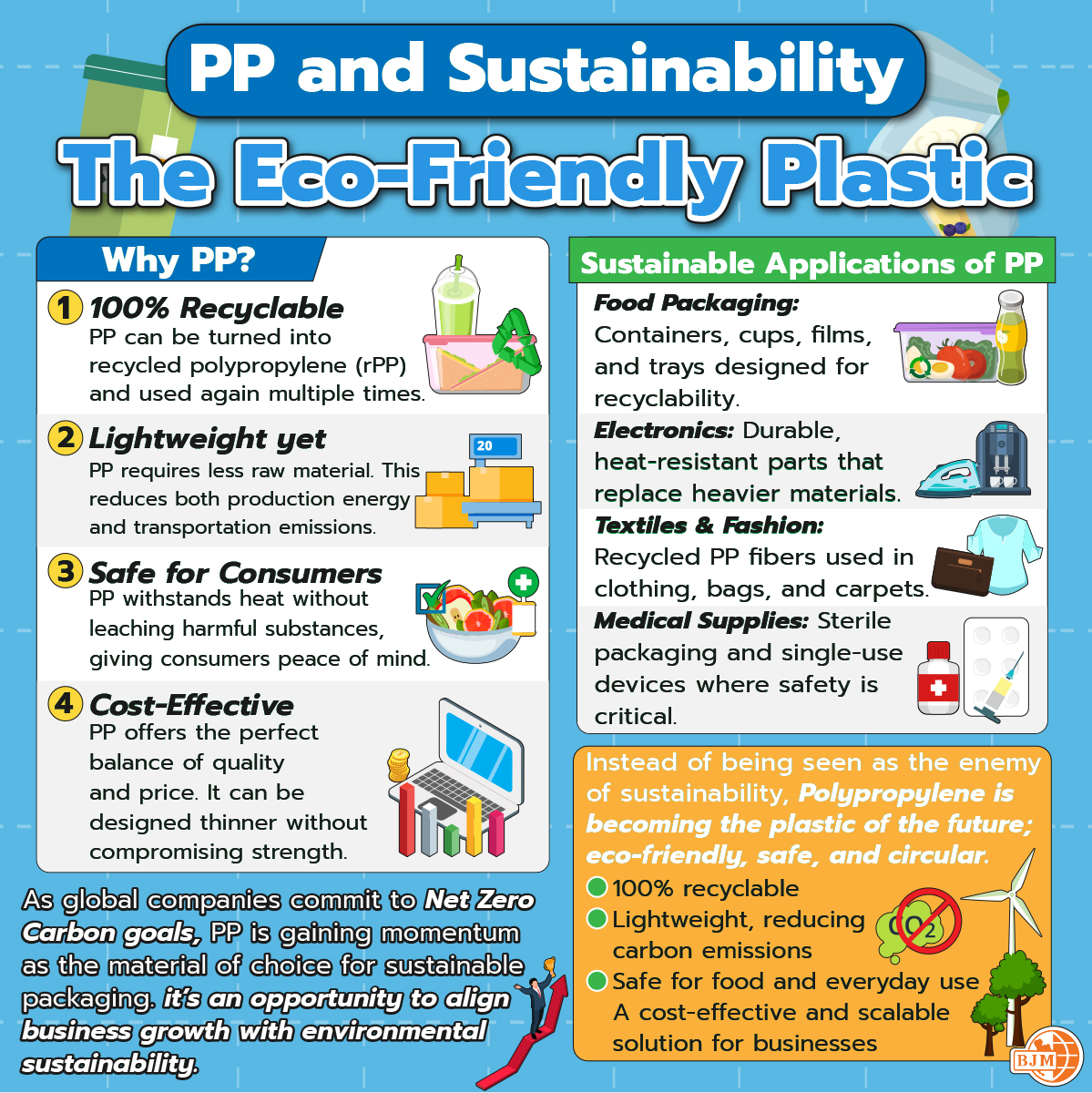

Why PP?

You may ask, “Isn’t plastic just plastic?” The answer lies in its properties and recyclability.

1. 100% Recyclable

PP is one of the few plastics that can be fully recycled without losing much of its original quality. With efficient collection and sorting systems, PP can be turned into recycled polypropylene (rPP) and used again multiple times.

2. Lightweight yet Durable

PP requires less raw material compared to alternatives while still offering strong performance. This reduces both production energy and transportation emissions, making it a lower-carbon choice.

3. Safe for Consumers

Widely used in food packaging, PP withstands heat without leaching harmful substances when used properly, giving both manufacturers and consumers peace of mind.

4. Cost-Effective

For businesses, PP offers the perfect balance of quality and price. It can be designed thinner without compromising strength, lowering material use while still ensuring safety and reliability.

♻️PP in the Circular Economy

The world is shifting toward a Circular Economy—moving away from the “take–make–dispose” model to one that emphasizes resource efficiency and reuse.

PP fits perfectly into this model. With proper packaging design (such as mono-material solutions for easier recycling) and robust collection systems, PP can be reused again and again. This reduces dependency on virgin plastics and minimizes waste leakage into the environment.

🍴 Sustainable Applications of PP

- Food Packaging: Containers, cups, films, and trays designed for recyclability.

- Electronics: Durable, heat-resistant parts that replace heavier materials.

- Textiles & Fashion: Recycled PP fibers used in clothing, bags, and carpets.

- Medical Supplies: Sterile packaging and single-use devices where safety is critical.

💡Challenges Ahead

While PP is highly recyclable, the biggest challenge lies in waste management systems. Without proper sorting and recycling infrastructure, PP can still end up in landfills or the environment.

This means collaboration is essential—between governments, manufacturers, and consumers—to ensure packaging design supports recycling and that infrastructure is in place to handle it efficiently.

🌍 PP and the Net Zero Future

As global companies commit to Net Zero Carbon goals, PP is gaining momentum as the material of choice for sustainable packaging. Its recyclability, lightweight nature, and safety make it an essential part of strategies to reduce environmental impact while keeping businesses competitive.

PP is redefining the way we think about plastics. Instead of being seen as the enemy of sustainability, Polypropylene is becoming the plastic of the future—eco-friendly, safe, and circular.

- ♻️ 100% recyclable

- 🌍 Lightweight, reducing carbon emissions

- 🍴 Safe for food and everyday use

- 💡 A cost-effective and scalable solution for businesses

With the right recycling systems and responsible design, PP is not a problem—it’s an opportunity to align business growth with environmental sustainability. 🌍♻️