As the world faces growing concerns about plastic waste, recycling has become an essential part of building a sustainable future. Among various types of plastics, Polypropylene (PP) stands out as one of the most recyclable and versatile materials. It is widely used in food packaging, storage containers, household products, and industrial components thanks to its durability, lightweight properties, and safety for food contact.

However, to ensure that recycled PP plastic is both safe and high-quality, the recycling process must be carefully controlled from start to finish — following proper scientific and industrial standards. When done correctly, recycled PP can regain almost the same performance as virgin material and be reused across multiple industries.

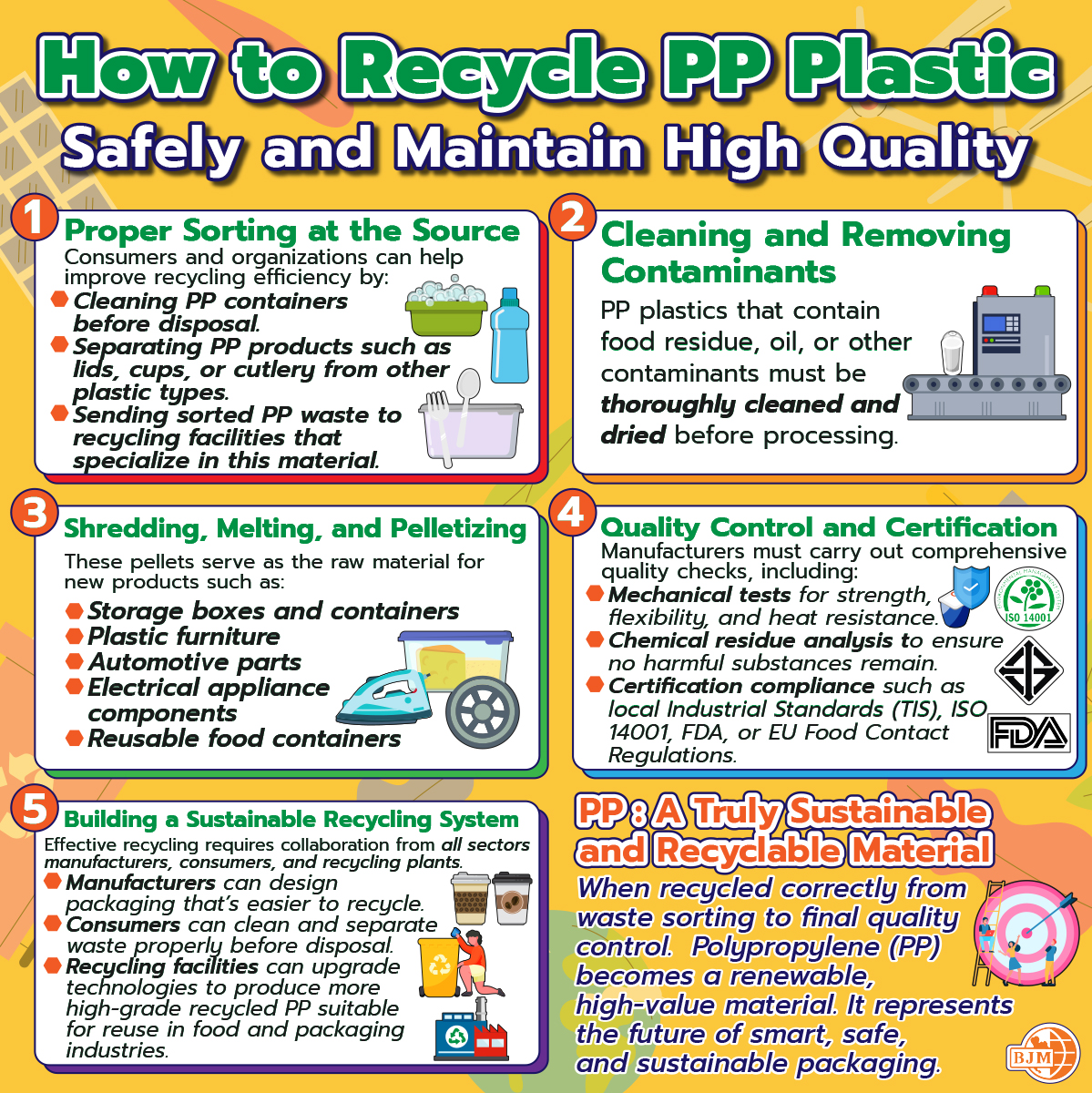

🔹 1. Proper Sorting at the Source

The first and most critical step in PP recycling is accurate sorting at the collection stage. Polypropylene is identified by the recycling code “5” (♻️ PP) . If mixed with other plastics such as PET or PVC, it can contaminate the recycling stream and reduce the quality of the final recycled material.

Consumers and organizations can help improve recycling efficiency by:

- Cleaning PP containers before disposal.

- Separating PP products such as lids, cups, or cutlery from other plastic types.

- Sending sorted PP waste to recycling facilities that specialize in this material.

🔹 2. Cleaning and Removing Contaminants

PP plastics that contain food residue, oil, or other contaminants must be thoroughly cleaned and dried before processing. Residues not only affect the quality of recycled pellets but also cause odor and discoloration.

Modern recycling facilities use advanced washing systems and filtration technologies to remove impurities effectively. This results in cleaner, odor-free PP flakes that can be safely reused, especially for non-food applications or durable goods.

🔹 3. Shredding, Melting, and Pelletizing

After cleaning, the PP waste is shredded into small flakes and then melted at around 200–250°C to form recycled plastic pellets. These pellets serve as the raw material for new products such as:

- Storage boxes and containers

- Plastic furniture

- Automotive parts

- Electrical appliance components

- Reusable food containers

For applications that involve direct food contact, only Food-Grade Recycled PP should be used. These materials must go through stringent purification and testing processes to ensure consumer safety.

🔹 4. Quality Control and Certification

To guarantee the performance and safety of recycled PP, manufacturers must carry out comprehensive quality checks, including:

- Mechanical tests for strength, flexibility, and heat resistance.

- Chemical residue analysis to ensure no harmful substances remain.

- Certification compliance such as local Industrial Standards (TIS), ISO 14001, FDA, or EU Food Contact Regulations.

These standards ensure that recycled PP materials are safe, consistent, and comparable in quality to virgin plastics.

🔹 5. Building a Sustainable Recycling System

Effective recycling requires collaboration from all sectors — manufacturers, consumers, and recycling plants.

- Manufacturers can design packaging that’s easier to recycle by using mono-material structures or easily removable labels.

- Consumers can clean and separate waste properly before disposal.

- Recycling facilities can upgrade technologies to produce more high-grade recycled PP suitable for reuse in food and packaging industries.

When everyone works together, we create a true circular economy, where plastic is treated as a valuable resource rather than waste.

🔹 PP : A Truly Sustainable and Recyclable Material

Recycling PP plastic not only reduces environmental impact but also helps businesses cut costs and enhance their sustainability image. With proper handling and advanced recycling technology, PP can be reused multiple times without compromising its strength or safety.

When recycled correctly — from waste sorting to final quality control — Polypropylene (PP) becomes a renewable, high-value material that supports both economic and environmental sustainability. It represents the future of smart, safe, and sustainable packaging.